The Undeniable Reality

A Promotional Brief on Future Textiles

Excerpts from the soon to be published Research Paper. Conceptualised by Philip Warner and Co-Funded by the Warner Research Institute

Research and compile by Abu Naser Md Ahsanul Haque, A/Prof Maryam Naebe. Institute for Frontier Materials, Deakin University, Geelong, VIC 3216, Australia

Paper Summary

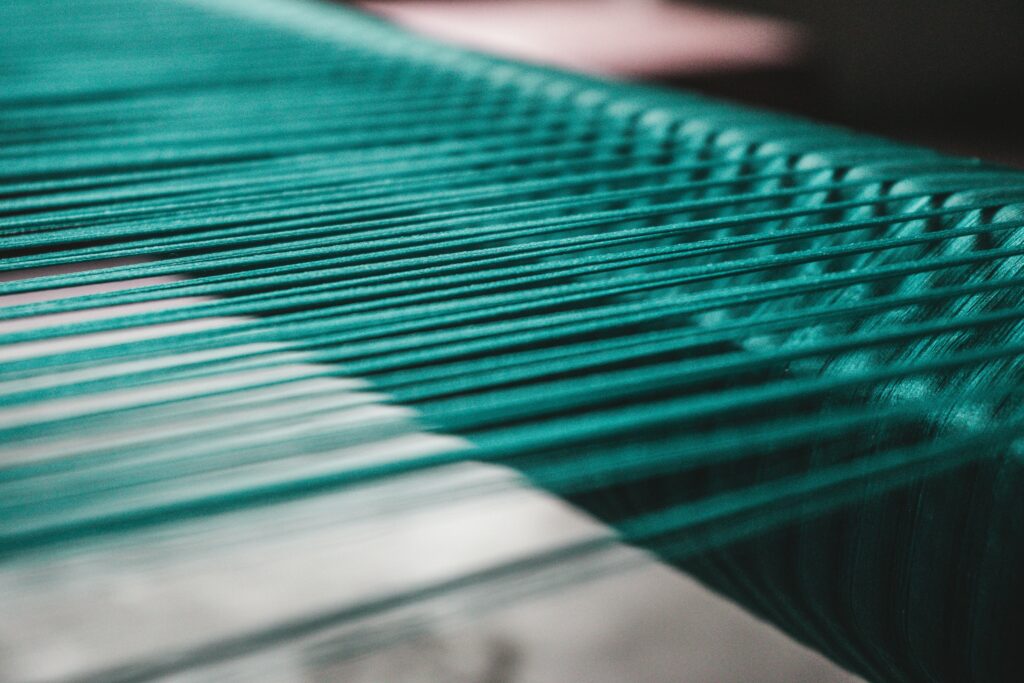

The textile industry is undergoing a critical transformation due to its ongoing dependence on synthetic fibres derived from fossil fuels. The shift from natural to synthetic fibres, primarily polyester, has led to severe environmental challenges, including greenhouse gas emissions, microplastic pollution and

chemical contamination. Even if one ignores the 2050 Paris Accord it is estimated that fossil fuels will likely be depleted between 2070 and 2090. Further, the rise of “fast fashion” has intensified textile waste, leading to overflowing landfills with non-degradable textiles that are causing environmental

imbalance. There is an undeniable necessity to change. Change of this magnitude takes a significant amount of time.

Moreover, not only are the synthetic fibres affected, but the entire value chain of manufacturing and processing, production and handling including natural fibres along with their wet treatments, pose significant environmental hazards. Environmental pollution is present throughout the entire textile

manufacturing process, from beginning to end. Taking immediate action is crucial. Before devising a solution, it is essential to identify the historical trends, properties, and chemistry of textile fibres and the alternatives that have already been proposed. Recognising the current global

sustainability trends and technological advancements, such as Industry 4.0 technologies, is crucial. These technologies have significantly improved our quality of life and are continually evolving and to consider how their integration with the textile industry over the next decades could drive modernisation and support effective circular garment production.

The White Paper “Future Textiles” examines the likely near-future scenarios and identifies the research and innovation still required to achieve those goals. It is evident that a new form of textile production is critical. It also showssignificant opportunities in the future market, especially in clothing. This hopes

to address the environmental, energy, material, and waste issues currently prevalent in the of machinery, labour, spinning, weaving, cutting, and sewing departing from age-old concepts in textile manufacturing. It would also pave the way for a dramatic shift in garment design and fashion.

If significant technological advancements are not achieved by 2050, the required reduction of non-biodegradable synthetics will create a demand/supply gap that increased natural fibres alone cannot fill. Developing textiles with specialised materials and construction techniques that allow for

deconstruction and reconstruction, a circular material solution, is a clear solution. In essence, human progress into textiles fundamental techniques of spinning, weaving, then later cutting, and sewing was initially a huge advancement from the use of animal skins but that was

developed thousands of years ago. That base manufacturing technology continues to dominate the industry today.

Previously anchored in natural fibres like cotton, wool, and silk, just over 100 years ago the industry experienced a major paradigm shift with the discovery of synthetic fibres. This advent revolutionised the industry offering a range of advantages over natural fibres. They are produced at a lower financial cost, greater durability, superior strength and elasticity, requiring less water and land resources compared to agriculture. Polyester, nylon and other synthetic textiles now dominate the market. However, the unforeseen problems were not understood back then. Polyester now accounts for over 60 % of global fibre production, with its demand projected to grow as the global population, and disposable income and consumerism expand.

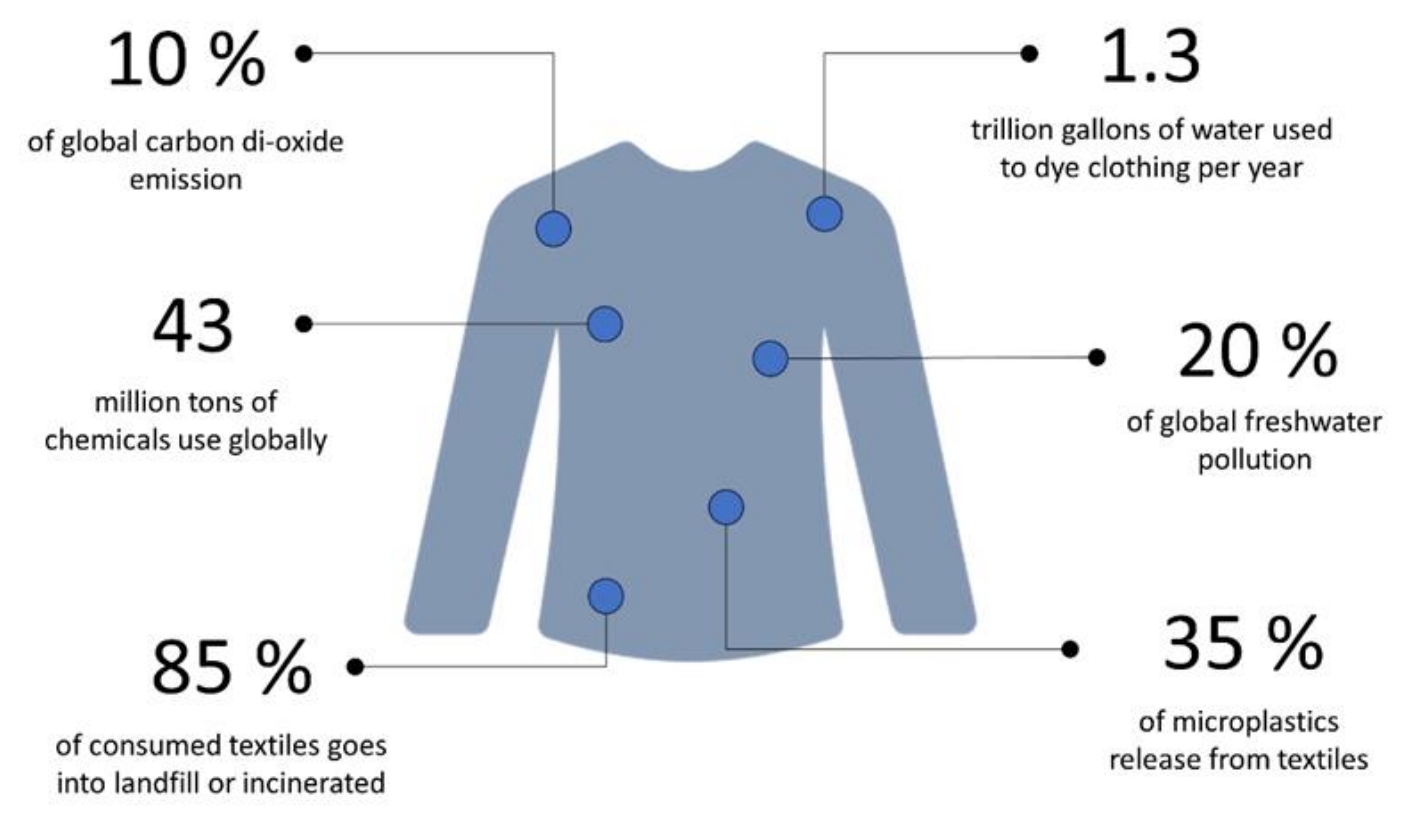

Despite their immediate cost benefits, the production and disposal of synthetic fibres pose severe environmental issues that will be passed on to humanity and the planet at a devastating cost. The manufacture of synthetic textiles is heavily reliant on petrochemicals, making it a substantial contributor to greenhouse gas (GHG) emissions. The entire lifecycle of these fibres—from raw materials to end-of-life disposal—saturates the environment with pollutants. It is estimated that the textile industry is liable for around 10 % of global GHG emissions, a substantial portion of which originates from synthetic fibre production. The most dangerous consequence of synthetic fibre use (and continued recycling) is the release of microplastics that enter ecosystems. These microplastics persist in the environment, posing threats to marine life, animals and plants and human health. Further, the production of textiles requires numerous chemicals, including dyes and finishing agents. These often contain hazardous compounds that can leach into soil and water systems.

Figure 1: The environmental concerns for textile manufacturing.

The surge in “fast fashion” and the frequent turnover of fashion collections—have intensified all these issues. Consumers are purchasing more clothing than ever, but they are also discarding garments at an unprecedented rate that end up in landfills. The finite nature of fossil fuels means that their continued utilisation for textile production is unsustainable in the long term.

Addressing these and other concerns requires a multifaceted approach involving governments, researchers, industry stakeholders, policymakers, and consumers. The textile industry stands at a crossroads, with the opportunity to redefine its relationship with the environment and resources. This paper explores massive opportunities for future research in textile manufacturing by integrating sustainability, innovation, and responsible production methods.

These approaches are forward-looking and technologically advanced, with significant potential in the coming years. This 90-page paper is structured into four chapters, each progressively focusing on Future Textiles.

Chapter 1. A Brief History to Present presenting key information on the historical development of textile fibres and manufacturing processes,

Chapter 2. Hazards in Current Textile Processes, this deals with the extent and primary causes of environmental hazards,

Chapter 3. Industry 4.0 and the Sustainability Trend, here the discussion moves forward through sustainability and technological trends to forecast future directions.

Chapter 4. Road to the Future Textiles, rationalises the theoretical foundations essential for designing the prerequisites of future advancements, envisioning a scenario where individuals can design and create their clothing at home with the simple press of a button, and deconstruct and reconstruct them

as many times as needed.

We now stand at a critical point where the need for sustainable practices and innovative solutions is more urgent than ever. The demand for change is undeniably inevitable. To address the pressing issues, a coordinated effort involving industry stakeholders, policymakers, researchers, and consumers is

essential. The following conclusions outline are the necessary steps for key players to navigate the path towards a more sustainable textile future.

Sustainable materials. Transitioning from fossil-fuel-based fibres to bio-based alternative materials is a crucial step. Innovations in bio-based materials need to be developed at scale and integrated into mainstream textile production. Additionally, widening the resource base to include underutilised natural fibres will help diversify and stabilise the supply chain.

Sustainable colouration. Traditional dyeing and printing processes are resource-intensive and contribute to chemical pollution. Bacterial colourants, which utilise microorganisms to produce natural dyes, present a sustainable and scalable alternative. This eco-friendly technology can potentially

minimise the use of harmful chemicals and water.

Green chemical processes. The use of chemicals in the pretreatment, dyeing, printing, and finishing poses significant environmental and labour health risks. Industry standards and regulations will ultimately be updated to mandate the use of eco-friendly chemicals. Collaboration between chemical companies, textile manufacturers, and regulatory bodies will be crucial to drive this transformation.

Separation and reuse. Fast fashion could become even more rapid, stylish, and entirely waste-free if the majority of textile and garment materials were designed to be reusable. Recycling of consumed textiles is complex but is a necessary process to reduce textile waste and promote a circular economy

over the 20 years. Technologies like Triboelectric separation use electric charges to sort fibres enhancing recycling efficiency. Whatever the next generation materials and/or technology is used will need to address all the challenges we have highlighted Future Textiles paper.

Circular garment production. The idea of circular garment production at a domestic level in the future is ambitious but feasible. This can be done by taking advantage of Industry 4.0 technologies and with a keen focus on sustainability. The fashion industry can support this by offering innovative designs that

more easily enable the construction, de-construction and sorting and re-construction of garments.

A sustainable path forward. The textile industry faces a dual challenge of environmental degradation and resource scarcity. The journey towards sustainability is complex and requires sustained effort and innovation. However, the potential benefits—for the environment, society, and the economy—are immense. By embracing sustainable practices, collaboration, creative thinking and research the Australian textile industry can not only mitigate its negative impacts but also become a leader in the global movement towards a more sustainable and resilient future.

Imagine a not-so-distant future in which designing and creating your garments is as easy as a keystroke on your laptop or smartphone. Scroll through your library of fashion likes. Choose for the occasion. See what it looks like on a graphic model of yourself, then click print. Instantly, a machine in your laundry begins the process of transforming the sanitised materials from your recently worn garments in an advanced 3D type printer and produces your next creation ready to wear in the morning. The best part? You have the freedom to change your mind at any moment and fashion another garment with a fresh design by simply placing your latest creation back into the machine.

The concept for the research and production of “Future Textiles” paper began in 2020 and has taken 2 years to write. When published it will be free to all who have an interest in evaluating the unavoidable challenges and potential path to solutions. Embracing and solving the challenges offers significant rewards for those who successfully achieve what is inevitable.

Yours sincerely,

Want to learn more?